Fig. 6

Download original image

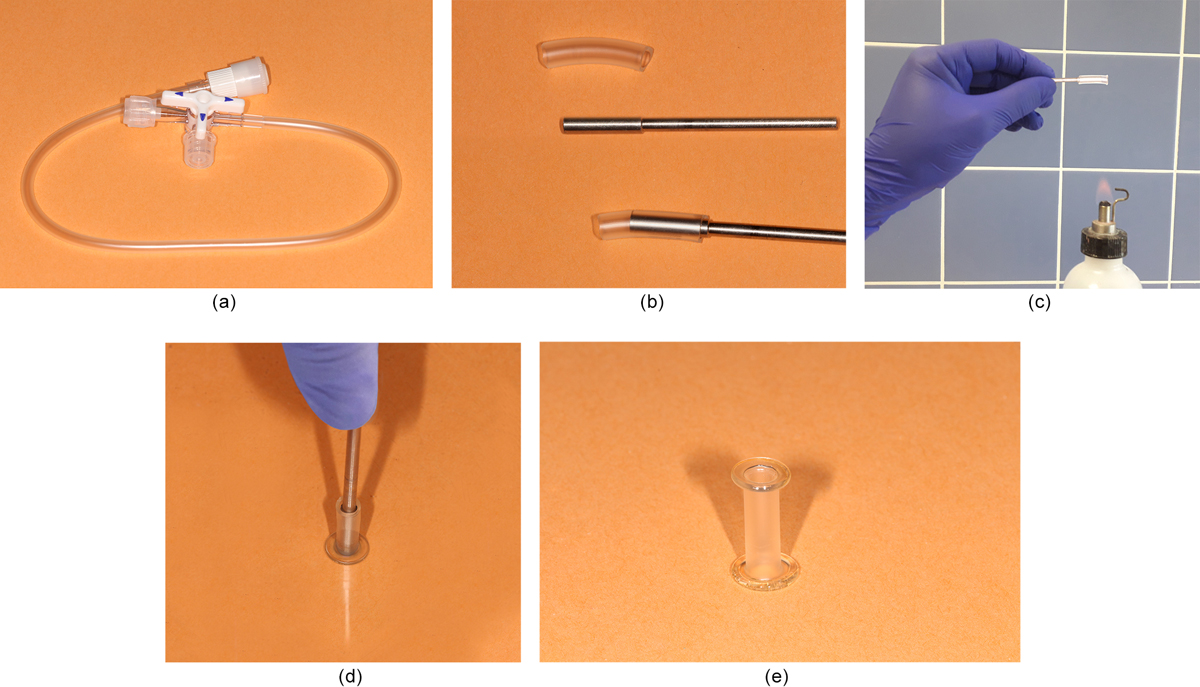

A method for manufacturing a decompression cannula. The idea is to shape a flange at each end of the tube to prevent the cannula from falling outside, or inside the cyst. Depending on the diameter required, any thermoplastic medical plastic tube can be used (intravenous infusion line, nasogastric tube, surgical suction pipe). When the OKC contents is very thick, a wider internal diameter should be chosen to allow the white lumps to be flushed out. (a) In this example, a polyvinyl chloride (PVC) intravenous infusion line can easily be cut to the appropriate dimension. (b) A metal mandrel is inserted in the tube, to handle it and maintain its shape while soft. The use of a mandrel represents an improvement of the technique initially described by a Danish author (Dr A Nielsen) in 1988 [40]. The mandrel diameter should be the same as the internal diameter of the infusion line. (c) The end of the tube is held above a flame, while rotating the mandrel to distribute the heat. (d) When soft, the tube tip is pressed against a glass plate until it cools. (e) The same process is repeated on the other end to get a double flanged tube. Before surgery, the tube is soaked in peracetic acid and thoroughly rinsed with distilled water.

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.